The wine growing regions of California are in need of large storage facilities for barrel and case storage. While underground caves provide an ideal thermal environment they are not practical in every situation. Above ground storage facilities, which would have the same strict requirements for maintaining temperature and humidity, could provide the required space while functioning as icons of the wine-making industry. It has been difficult, however, to find a suitable construction system that integrates the technical, practical, and aesthetic requirements. The most common approach; to use a standard steel frame "butler building,” and outfit it with enough layers of insulation to keep energy costs within reason, will never conjure up romantic images of the wine makers art.

What is needed is a new form of construction that can produce a large structure of enduring stature – a building standing in the ancient tradition of architecture – that resolves the strict requirements for an above ground wine storage facility. The ideal structure would be cost effective, energy efficient, fire resistant, have outstanding structural performance, particularly in response to seismic shaking, and be an investment that will last into the next century and beyond.

This post outlines the three key reasons why owners should consider smart building systems for their next winery facility project.

Smart Building System

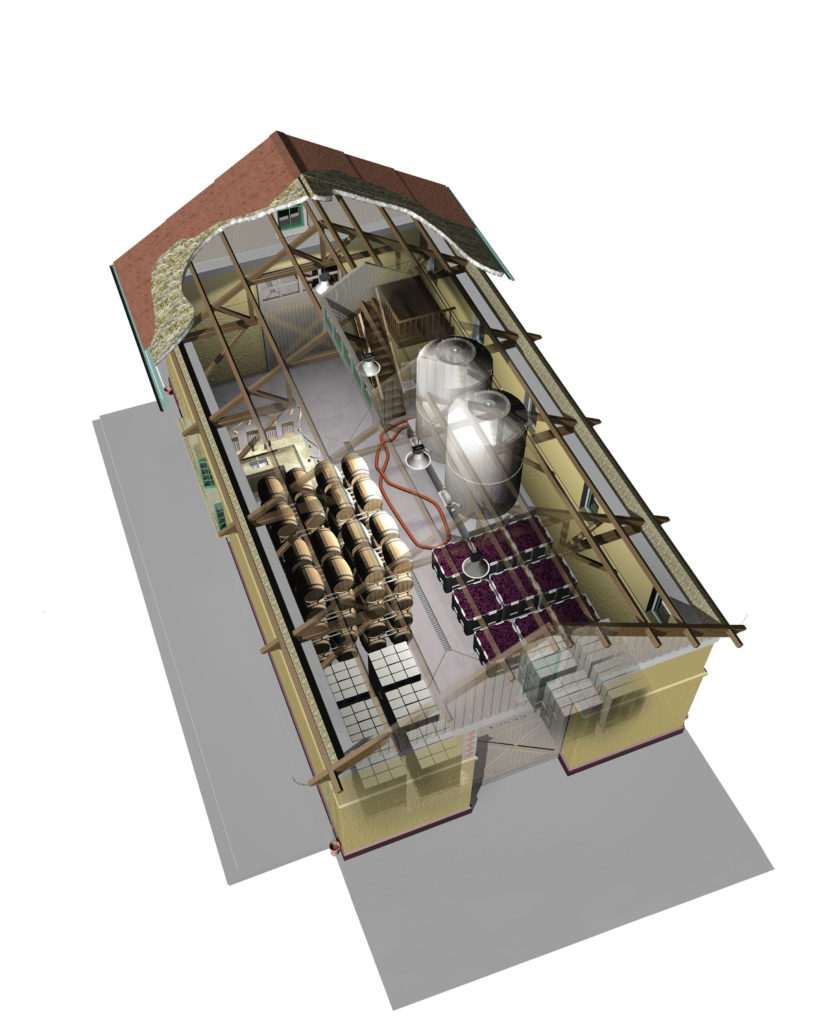

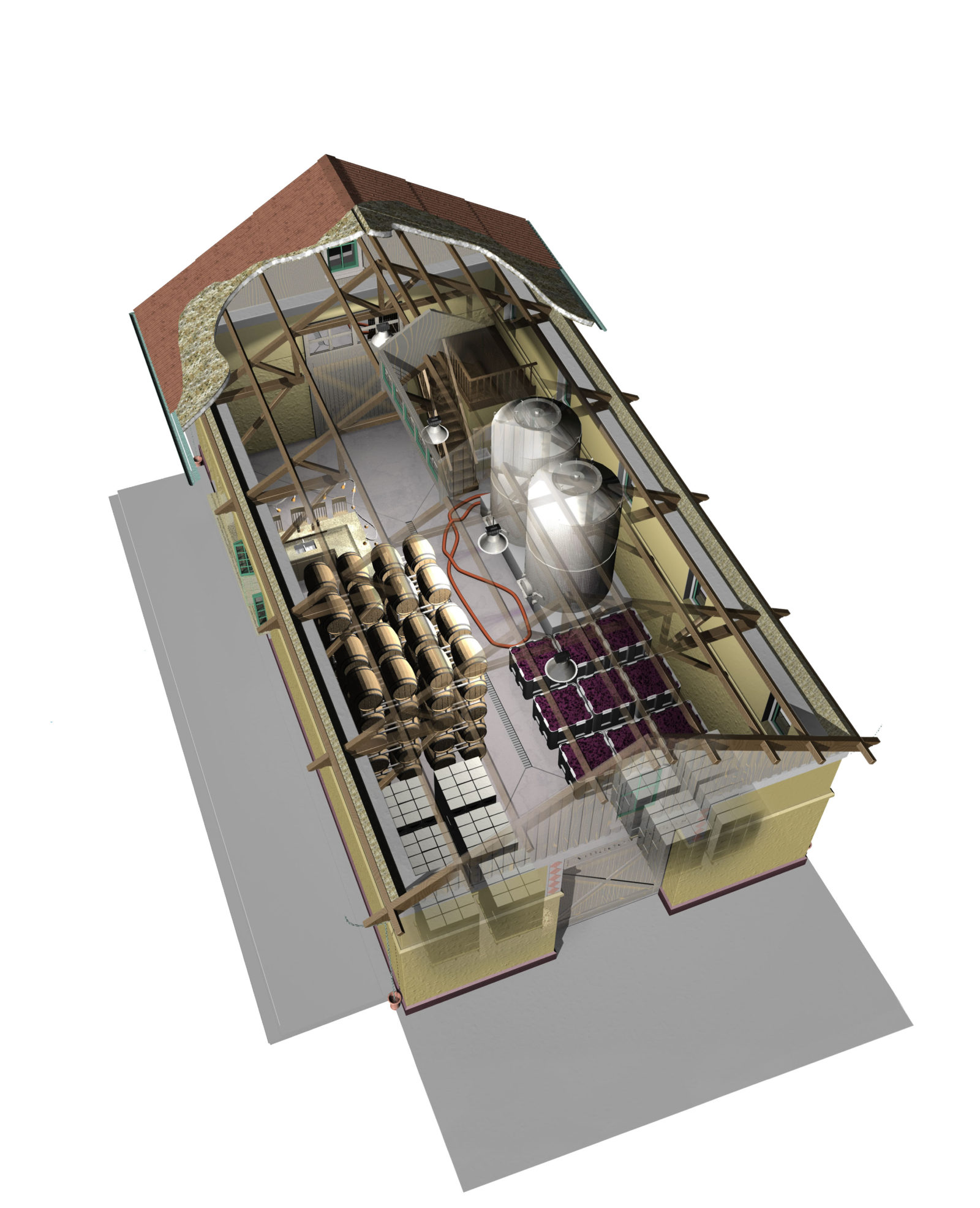

The Energy Mass ™ smart building system [1] is a patented combination of R-100 insulation, steel rebar, glass fiber reinforced polymer and concrete. It is capable of providing above ground cave structures of great size and elegance which are expressly suited to maintaining a constant interior environment with more temperature control and stability than even below ground caves. The Energy Mass ™ is not size restrictive. Hundred thousand square foot structures with forty-foot eaves can be constructed, making the system practical for complete winery facilities including those incorporating multi-level tank layouts. The double wall concrete shell provides an unparalleled level of thermal, structural, and fire performance, while promoting architectural adaptation to various sites, building types, and the aesthetic preferences of individual wineries. It is architecturally suited to construction of cellars, visitor’s centers, administration buildings, and villas as well as warehouses to create a holistic building ensemble.

The Energy Mass ™ smart building technology produces a masonry wall that is nearly two feet thick. Whether left rough, cut with a wooden float, or troweled into a smooth finish the geometry produces a building with deep reveals around entrances and windows -- reveals that are reminiscent of an age when buildings were made to endure. The gently undulating wall communicates its authentic underpinnings. The pitched roof, with large overhangs to shelter the walls, strikes a primal chord and harmonize with the landscape in a way that flat roofed buildings fail to do.

Above-Ground Climate Control

People have appreciated the thermal properties of masonry buildings for centuries. Thick mud adobe walls, stone walls, and rammed earth walls help to control the interior climate of a building through their inherent ability to “store” thermal energy and release it at a later time. It is this property known as thermal storage or thermal mass that functions best in Mediterranean climates. These climate zones have hot days and cool nights. The solid masonry walls “store” the cool from the nighttime and “release” it during the day. Conversely, it also stores the heat from the day, releasing it during the night. Climate control systems that utilize thermal storage techniques rely on the day-night temperature swings. When the daytime temperature and night time temperature have less of a differential passive thermal storage alone will not be effective in controlling the interior climate. In these cases it is necessary to incorporate some form of refrigeration. Unlike the forced air systems used in conventional barrel storage buildings the Energy Mass ™ smart building system uses radiant cooling via chilled water running in tubes through the wall. Because radiant cooling doesn't dry out the air, the standard air conditioning misters (along with the attendant problems of mold) are eliminated.

Evaporation from the wine barrels in a typical barrel room can run as high as 8% but with misters and other controls can be brought down to 3 - 4%. The Energy Mass ™ smart building technology reduces the evaporative loss to under 1% saving thousands to hundreds of thousands of dollars annually in evaporative losses alone.

System Costs

The Energy Mass ™ smart building technology costs more than standard construction but in nmerous life cycle cost analyses completed over the years -- the only way to truly evaluate building costs -- payback from energy savings, maintenance and evaporative losses pay for the increased costs in under four years. And, in many cases the savings pay for the entire building in less time than it takes to pay off the mortgage. After three or four years the wine business will be making additional money every year by giving less money to the power companies, spending less in maintenance and dolling out less for the "angel's share."

Resilience

Earthquakes and fires can, and do, cause millions of dollars in property damage each year. The Energy Mass ™ smart building system is extremely resistant to earthquakes – exceeding code values in some building types by as much as 300%. The wall structure is similar to that of an airplane wing with thin skins of material (concrete in this case instead of aluminum) separated a distance and tied together with spars, which in the Energy Mass ™ system are made of high strength non--heat conducting glass fiber reinforced polymer. The resulting geometry gives the wall unprecedented out - of - plane performance in an earthquake.

The same properties that give the system superb thermal performance also give it excellent fire resistance. To truly appreciate the fire performance, do the following experiment. Take a standard plastic sandwich bag, light a match, hold the flame next to the bottom of the bag and watch it burn a hole right through it. Then take another sandwich bag (from the same box) and fill it with water. Do the experiment again and watch as the match burns your fingers struggling to burn a hole through the thin plastic film. Don't worry, it won't, because the water absorbs the heat, thus protecting the flimsy plastic.

Concrete contains bonded water as part of its chemistry. When fire attacks, the water acts much like the water in the experiment absorbing and dissipating the heat. Before the concrete can burn, or even heat up above the boiling temperature of water, this water of hydration must be evaporated. Driving out the bonded water requires an enormous amount of heat energy. However, if the fire is hot enough, long enough the exterior membrane will begin to break down. This is why in extreme fire locations the outer skin of the Energy Mass ™ smart building system is constructed with radiant tubes like those on the inside for cooling. However, in this instance the running water is used for two purposes (i) siphon off heat from a south or west facing wall for use in heating water for domestic use or winery operations and (ii) safeguard the building and its contents during a once in a hundred-year blistering fire. Like the plastic bag example, the wall cannot burn or even heat up so long as the water keeps flowing.

A building is more than an investment of time and money. It is an icon of an era, both a product and embodiment of the functional, social, and economic forces that shaped it. Timeless buildings – those that remain through the ages -- are unique constructions. They sit perfectly in their particular environment, reaching out with wings of light that capture the landscape to create courtyards and terraces. They are the product of local resources and talents. They are a reflection of the values of the people that made it.

[1] Developed by Gary Black, licensed professional engineer, president of Integrated Structures Inc. and professor of architecture at the University of California, Berkeley’s College of Environmental Design. The system has been extensively tested under his guidance at the Universities' Earthquake Engineering Research Center and has been employed in the construction of numurous projects, including wineries, residences, churches and vineyard estates. The smart building technology was recently accepted by the Guam Housing Authority for an affordable housing solution on the typhoon ravaged United States military island.

One of the main reasons I created GearBrain was to help simplify all this new emerging technology which can turn your house into a smart home. I found there was a ton of new products coming to market and no one was helping the consumer determine which were the right ones for their home. They also weren’t helping consumers figure out where to start to build a smart home or even add a few connected devices which could help you save money or provide protection from unwanted visitors. Therefore, I am writing this article to help you learn where to start and how to build the right smart home system for your house. Since GearBrain tests these smart devices in real homes, we have learned what it takes to get started in our new connected world. Below you will find links to our articles which will be a valuable resource for you prior to starting to build or while you are building your new connected home.